Engine monitoring

FFM100

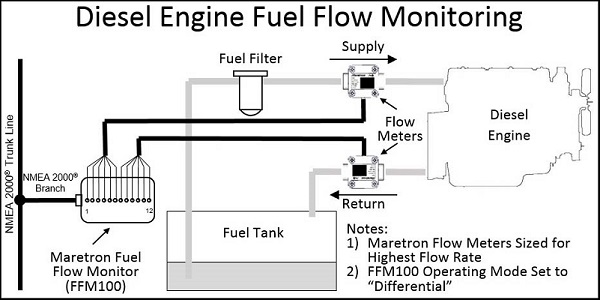

Maretron's FFM100 provides precision fuel flow information to help optimize fuel consumption, which can save thousands of dollars in fuel operating cost. The FFM100 uses state-of-the-art, positive displacement metering technology for unprecedented accuracy. In fact, the accuracy of the FFM100 is nearly that of commercial vessel systems costing tens of thousands of dollars, yet the FFM100 cost less than existing recreational systems found on the market today. Additional benefits of the positive displacement metering technology are the elimination of flow conditioning components such as straighteners and pulsation dampers. Other flow meter technologies require flow conditioning components that increase system and installation cost. The FFM100 also uses true temperature compensation with embedded temperature sensors within the meters. The returning fuel is generally hotter than the supply fuel and if not properly compensated, inaccuracies as much as 5% can occur in computing the engine's fuel consumption. The FFM100 also detects momentary reverse flow in the fuel lines due to fluctuating pressure caused by the injection pump. Less accurate systems count the reverse fuel flow as part of the consumed fuel where the FFM100 properly accounts for momentary reverse flow.

Lastly, the FFM100 can be used for fluid types other than fuel (e.g., water, oil, etc.) by ordering the appropriate flow sender.

The FFM100 is NMEA 2000® certified so you can view any and all information anywhere on the vessel using a compatible NMEA 2000® display. The FFM100 is a key component of Maretron's N2KView® vessel monitoring and control system.

Specifications:

- FFM100 converts a variety of flow senders (e.g., fuel, water, etc.) to NMEA 2000® Network Data

- All flow senders ordered separately depending on application (i.e., single fuel flow sender for gas engine, dual fuel flow senders for diesel engine, water flow sender for sea water, etc.)

- Fuel flow senders facilitates fuel consumption optimization for reduced fuel operating cost

- Fuel flow senders use positive displacement metering technology for superior accuracy over other measurement technology such as turbine meters

- Fuel flow senders do not require costly fuel conditioning components like flow straighteners and pulse dampers

- Fuel flow senders implement true temperature compensation with precision built-in thermistors for increased accuracy

- Fuel flow senders automatically detect reverse flow due to fluctuating pressure difference from injection pumps

- Fuel flow senders pass particle sizes up to 70 micrometers (diesel fuel filters normally filter down to 2 micrometers to prevent clogging injectors)

Applications: Diesel Fuel Flow Monitoring, Gasoline/Petrol Fuel Flow Monitoring, Cooling Water Flow Monitoring

Download documents: FFM100 Datasheet FFM100 Flyer FFM100 User Manual 1.4

J2K100

Maretron's J2K100 attaches directly into J1939 networks of compatible engines, transmissions, and gensets and converts the J1939 engine data to the NMEA 2000® marine digital interface. Critical engine, transmission, and genset data is then distributed throughout the vessel over a single cable where it can be monitored by any NMEA 2000® compatible display. All the information you need is available anywhere and everywhere you need it.

The J2K100 only listens to the J1939 network and draws no power from it (power is derived from the NMEA 2000® interface). The J2K100 does not transmit any information over the J1939 network so it will not interfere with existing engine control or status data in any way.

The J2K100 can also be used as part of a complete fuel computer. Simply connect the J2K100 together with the Maretron universal display (DSM250) or DSM410 and GPS antenna/receiver (GPS200) and you have a system capable of displaying gallons per hour and/or miles per gallon.

Specifications:

- AC Generator Current

- AC Generator Frequency

- AC Generator Voltage

- Tachometer

- Engine Hours

- Coolant Pressure

- Coolant Water Temperature

- Engine Oil Pressure

- Engine Oil Temperature

- Boost Pressure

- Fuel Rate Monitoring

- Charging Voltage

- Percent Engine Load

- Percent Engine Torque

- Rated Engine Speed

- VIN

- Software ID

- Transmission Gear

- Transmission Oil Pressure

- Transmission Oil Temperature

Aplications: Caterpillar, Cummins, Detroit Diesel, John Deere, Kohler, Onan, Perkins, Steyr, Volvo Penta, Yanmar

Download documents: J2K100 Datasheet J2K100 User Manual 1.4